Wood is one of the oldest building materials known to mankind. Although exhibiting exceptional structural behaviour, it was slowly replaced by man-made materials throughout the industrialization. Today, wood is again experiencing an increased use as a construction material in the building industry. As a regionally available and renewable resource with a negative carbon footprint, timber undoubtedly plays a major role in the current development towards sustainable, carbon neutral construction.

Wood’s singular performance behaviour and material characteristics come from its primary function as a naturally grown biological tissue. Unlike other construction materials, wood cannot be manufactured to a particular specification. All of its differentiated material properties are themselves intrinsic to its physiological role within the tree as a living organism and as such, they exhibit a great range of variation.

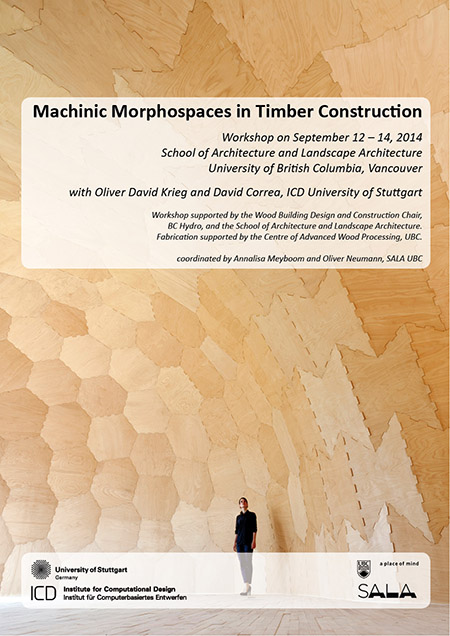

In traditional wood working the timber joint’s structural and aesthetical quality is achieved mostly through manual fabrication. Limited material supply and laborious production initially drove the development towards highly geometrically complex but performative joint designs. However, contemporary timber construction shows the same issues symptomatic for all industrial mass-produced construction techniques as the joint is being considered the most expensive part of the design. Industrialized wood processing machines were developed for fast mass-production at the expense of a much smaller design space – or machinic morphospace: the theoretical space of producible geometry in relation to the machine setup.

Current research in the field of digital fabrication in architecture is characterised by a shift from standardised CNC machinery towards more generic fabrication equipment such as industrial robots. The workshop will aim at utilising the vastly increased design space of modern digital fabrication through a bottom-up approach in timber construction and architecture. Accessing the material complexity of wood – in a meaningful way – requires a re-conceptualisation of architectural design as it necessitates the engagement of new computational design and fabrication tools.

After an initial analysis of wood, wood products and classic timber joints, the workshop’s goal will be to develop structurally performative and geometrically flexible timber joints in close relation to the material, the fabrication technology, and their application in a construction system.

The workshop is coordinated by Annalisa Meyboom and Oliver Neumann, SALA UBC.

It is supported by the Wood Building Design and Construction Chair, BC Hydro, and the School of Architecture and Landscape Architecture. Fabrication is supported by the Centre of Advanced Wood Processing, UBC.

Basic knowledge with Rhino 5.0 is required. Familiarize yourself with Grasshopper.

The workshop is fully booked.

Phase 1: Material research (completed prior to workshop)

Friday, September 12

12:30 Introductory Lecture: Material Computation, Brown Bag lunch lecture

14:00 Tour through the Centre for Advanced Wood Processing

15:30 Phase 1 Review: Material

17:00 Phase 2 Lecture: Machinic Morphospaces

Saturday, September 13

9:00 Independent group work and individual desk crit

16:00 Phase 2 Review: Joinery

18:00 Phase 3 Lecture: Material Systems

Sunday, September 14

9:00 Independent group work and individual desk crit

18:00 Phase 3 Review: material system

Phase 4: Digital Fabrication (schedule to be confirmed)