Programming Material Intelligence - Digital FUTURES 2018 Workshop

ICD Research Associates Tiffany Cheng and Dylan Wood led a workshop on "Programming Material Intelligence" at Tongji University, Shanghai as a part of Cyborg Futures, the 2018 edition of the DigitalFUTURES annual conference. Every year, more than two hundred students gather to engage with state-of-the-art digital fabrication and computational design tools.

The ICD workshop explored how advances in computational design and robotic fabrication can be used to design large parts with new types of autonomous, shape-changing behaviors.

Shape-Changing 3D-Printed Bio-Hybrid Components

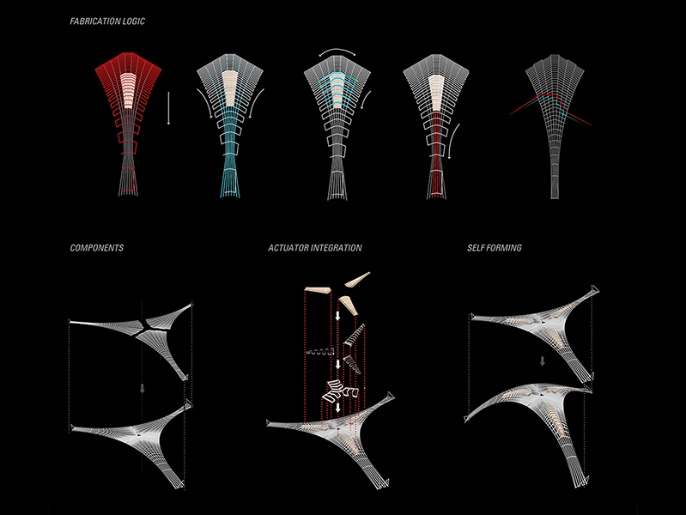

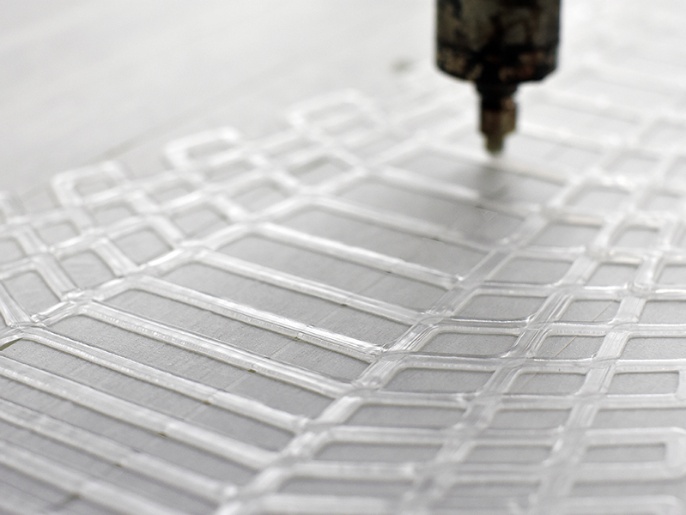

Material programming denotes a method of design in which functions such as movement can be encoded in the physical material and fabrication logic, in place of electronics and digital control. Following this methodology, climate actuated behaviors were designed and encoded into macro scale parts using additive manufacturing and an integrated combination of natural and synthetic materials.

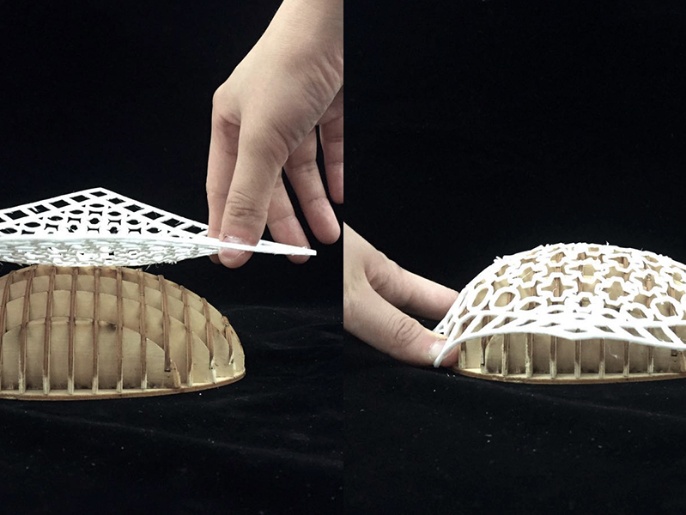

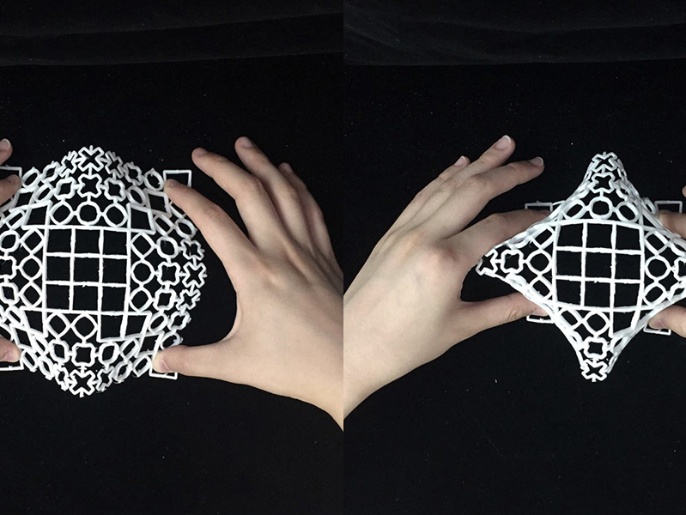

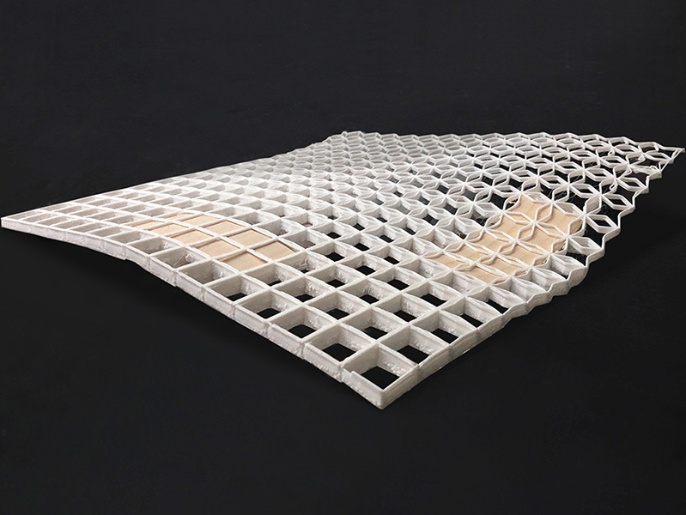

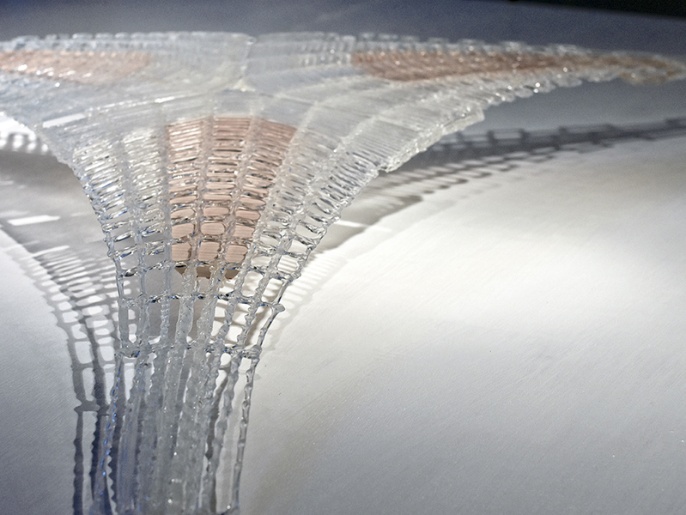

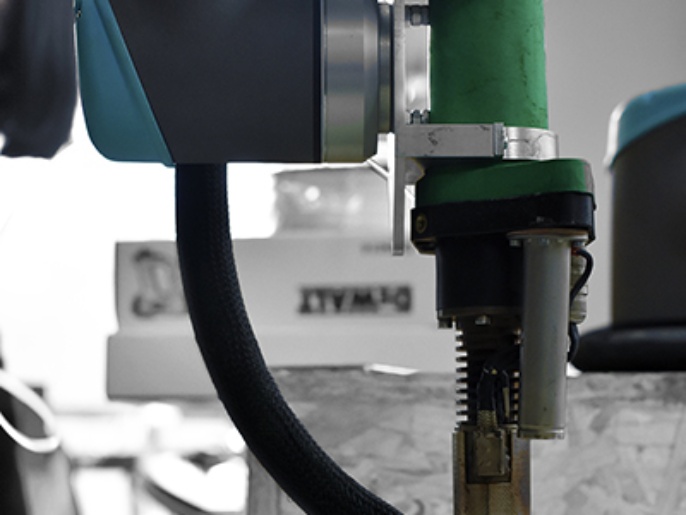

A computational design workflow developed by ICD was tested to investigate new multi-performance and material level tectonics. In the first phase, participants iteratively designed and 3D-printed parts with varying stiffness to gain an understanding of how variable material properties can impact the way an object moves, bends, and stretches. Next, teams of students explored the strategic placement of natural wood actuators within a component with varying material properties, as well as their tectonic integration with the 3D-printed armature. These explorations were then synthesized at full scale using a robotic extrusion process, resulting in a set of prototypes with shape-changing behaviors based on variable stiffness and integrated wood actuators.

The week-long workshop culminated in an exhibition, opening on July 7, 2018. The digital and physical catalogue of investigations from the workshop are currently on display at Tongji University in Shanghai.

ICD Institute for Computational Design and Construction

Prof. Achim Menges, Tiffany Cheng, Dylan Wood

FabUnion Tutor Assistant

Wang Xiang

Participants

Chen Cai, Yunyi Chen, Philipp Farana, Osama Hashem, Mu He, Kecheng Huang, Xiaobai Ji, Zhuoqun Jiang, Zeynab Kaseb, Tomas Vivanco Larrain, Siyu Li, Yige Liu, Jiaxin Nie, Yuchi Shen, Zexin Sun, Xuan Tang, Liu Yang, Zhefan Yu, Fei Yue, Tong Zhang, Qingyu Zhu

Organized and Supported by

CAUP Tongji University, Shanghai

FabUnion, Shanghai – Prof. Philip F. Yuan

Trendzone

ICD Research Associates Tiffany Cheng and Dylan Wood led a workshop on "Programming Material Intelligence" at Tongji University, Shanghai as a part of Cyborg Futures, the 2018 edition of the DigitalFUTURES annual conference. Every year, more than two hundred students gather to engage with state-of-the-art digital fabrication and computational design tools.

The ICD workshop explored how advances in computational design and robotic fabrication can be used to design large parts with new types of autonomous, shape-changing behaviors.

Shape-Changing 3D-Printed Bio-Hybrid Components

Material programming denotes a method of design in which functions such as movement can be encoded in the physical material and fabrication logic, in place of electronics and digital control. Following this methodology, climate actuated behaviors were designed and encoded into macro scale parts using additive manufacturing and an integrated combination of natural and synthetic materials.

A computational design workflow developed by ICD was tested to investigate new multi-performance and material level tectonics. In the first phase, participants iteratively designed and 3D-printed parts with varying stiffness to gain an understanding of how variable material properties can impact the way an object moves, bends, and stretches. Next, teams of students explored the strategic placement of natural wood actuators within a component with varying material properties, as well as their tectonic integration with the 3D-printed armature. These explorations were then synthesized at full scale using a robotic extrusion process, resulting in a set of prototypes with shape-changing behaviors based on variable stiffness and integrated wood actuators.

The week-long workshop culminated in an exhibition, opening on July 7, 2018. The digital and physical catalogue of investigations from the workshop are currently on display at Tongji University in Shanghai.

ICD Institute for Computational Design and Construction

Prof. Achim Menges, Tiffany Cheng, Dylan Wood

FabUnion Tutor Assistant

Wang Xiang

Participants

Chen Cai, Yunyi Chen, Philipp Farana, Osama Hashem, Mu He, Kecheng Huang, Xiaobai Ji, Zhuoqun Jiang, Zeynab Kaseb, Tomas Vivanco Larrain, Siyu Li, Yige Liu, Jiaxin Nie, Yuchi Shen, Zexin Sun, Xuan Tang, Liu Yang, Zhefan Yu, Fei Yue, Tong Zhang, Qingyu Zhu

Organized and Supported by

CAUP Tongji University, Shanghai

FabUnion, Shanghai – Prof. Philip F. Yuan

Trendzone

Contact information

Tiffany Cheng

Dr.-Ing.Research Group Leader | Material Programming