Fibrous Joints for Segmented Timber Shells

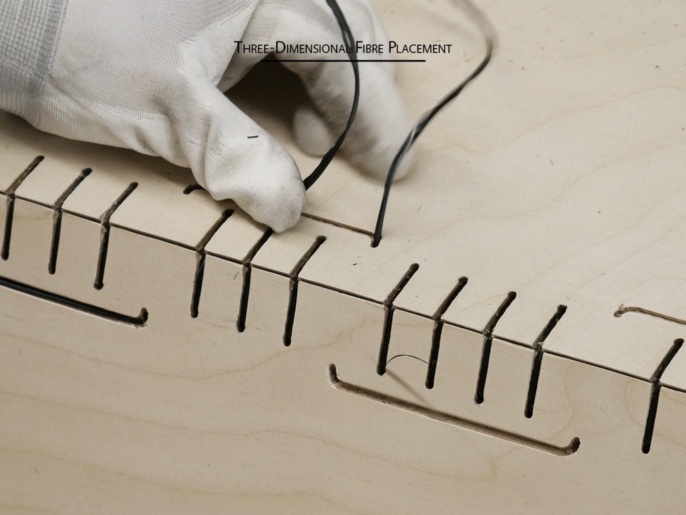

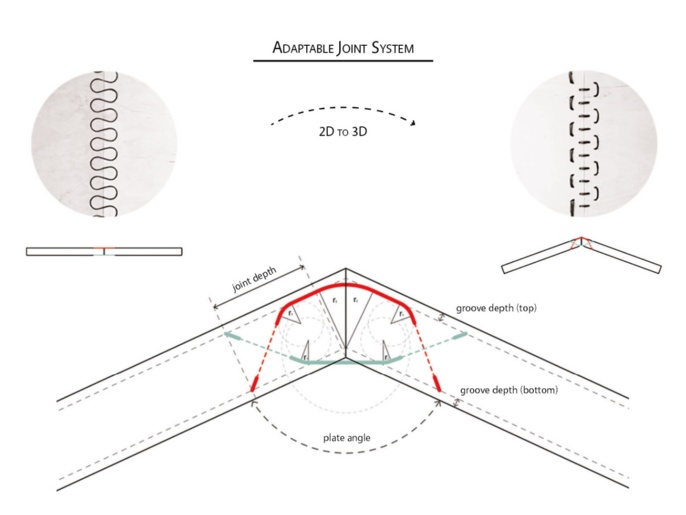

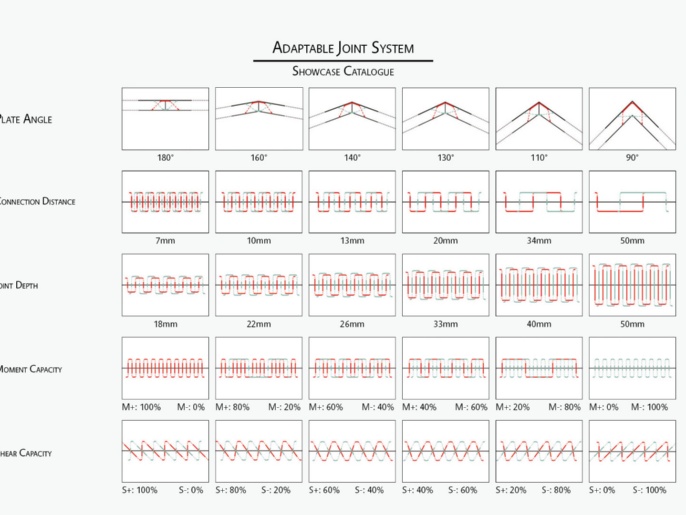

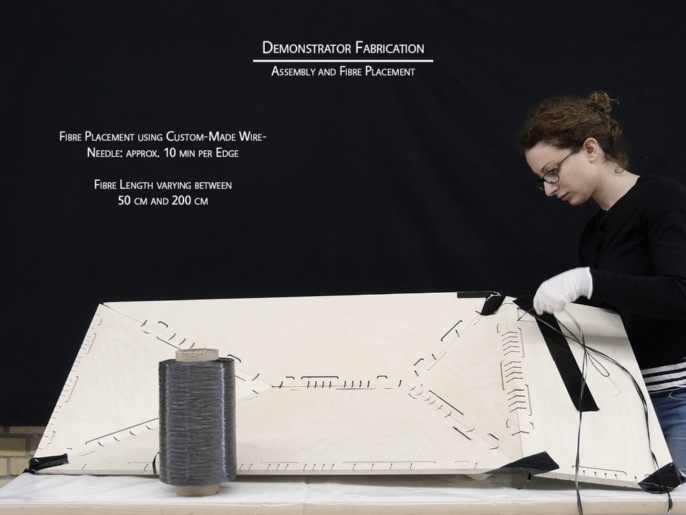

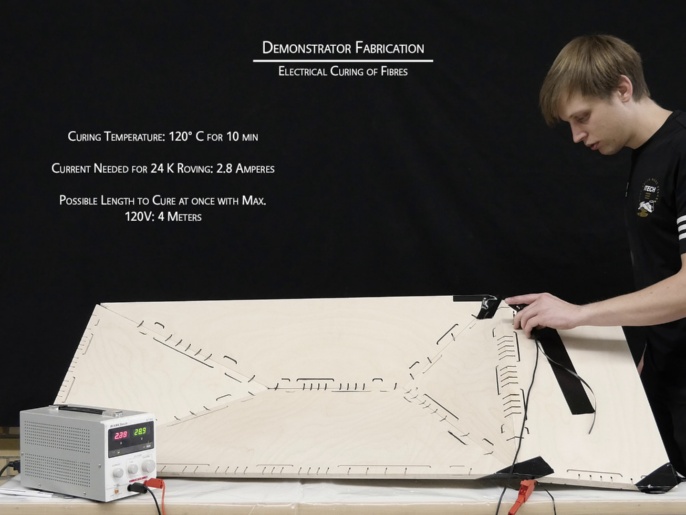

This Master Thesis introduces a novel approach for three-dimensional placement of Carbon Fibre Reinforced Polymer (CFRP) Tows inside prefabricated plywood plates to create fibrous bending resistant timber plate joints. Their density, orientation and position can be adapted to the calculated local forces in a segmented hybrid timber shell. Initial structural tests of the joints show promising results; especially their bending capacity seems hard to match with other integrated joining techniques. Using this approach, any dihedral plate angles between 90 and 180° can be achieved, which allows for gradual integration of various functional and structural aspects into segmented timber shells. Active CFRP rigidisation via Internal Resistive Heating is used to cure the Fibre Tows after they are placed inside the wood. This opens up the possibility of mobile on-site joining of large-scale structures with CFRP Tows independent of autoclave sizes. Finally, yet importantly, the joints’ structural capacity purely depends on the form-stability of the CFRP loops rather than any chemical interface. The CFRP parts can therefore be easily removed from the wood for disassembly, separation and recycling of the used materials. The final demonstrator showcases the structural integrity of the system and the geometric design freedom that derives from bending stiff joints in thin timber shell structures with variable dihedral angles. The robotic fabrication process enables customized joint situations for every single edge taking into account the simulated stresses in the structure.

ITECH M.Sc. Thesis Project 2017: Fibrous Joints for Segmented Timber Shells

Dominga Garufi, Hans Jakob Wagner

Thesis Advisers: Tobias Schwinn, Dylan Wood with Simon Bechert

Thesis Supervisor: Prof. Achim Menges

Second Supervisor: Prof. Jan Knippers

This Master Thesis introduces a novel approach for three-dimensional placement of Carbon Fibre Reinforced Polymer (CFRP) Tows inside prefabricated plywood plates to create fibrous bending resistant timber plate joints. Their density, orientation and position can be adapted to the calculated local forces in a segmented hybrid timber shell. Initial structural tests of the joints show promising results; especially their bending capacity seems hard to match with other integrated joining techniques. Using this approach, any dihedral plate angles between 90 and 180° can be achieved, which allows for gradual integration of various functional and structural aspects into segmented timber shells. Active CFRP rigidisation via Internal Resistive Heating is used to cure the Fibre Tows after they are placed inside the wood. This opens up the possibility of mobile on-site joining of large-scale structures with CFRP Tows independent of autoclave sizes. Finally, yet importantly, the joints’ structural capacity purely depends on the form-stability of the CFRP loops rather than any chemical interface. The CFRP parts can therefore be easily removed from the wood for disassembly, separation and recycling of the used materials. The final demonstrator showcases the structural integrity of the system and the geometric design freedom that derives from bending stiff joints in thin timber shell structures with variable dihedral angles. The robotic fabrication process enables customized joint situations for every single edge taking into account the simulated stresses in the structure.

ITECH M.Sc. Thesis Project 2017: Fibrous Joints for Segmented Timber Shells

Dominga Garufi, Hans Jakob Wagner

Thesis Advisers: Tobias Schwinn, Dylan Wood with Simon Bechert

Thesis Supervisor: Prof. Achim Menges

Second Supervisor: Prof. Jan Knippers