Wood is a natural fibre-composite and differs profoundly from other industrially standardized raw materials. Especially the anisotropic behavior, meaning the directional dependance of the material properties as well as the deliquescence, which is defined as the materials’ potential to absorb humidity from its surrounding environment – whether it be gaseous or fluid water – are crucial characteristics of wood. Based on these properties wood presents itself as a material, which interacts with its surroundings constantly and reciprocally. Through absorption of moisture and disposal respectively the material expands or contracts and undergoes dimensional changes. This process and the resulting (De-)Formation are usually considered negative side effects.

As part of this research project this characteristic capacity was observed, analyzed and evaluated especially concerning its potential for architectural application. The basic hypothesis of the conducted experiments can be summarized as such: It is possible to strategically use the hygroscopic behavior of wood to develop an architectural material system that interacts with its environment and develops functional capacities through this behavior.

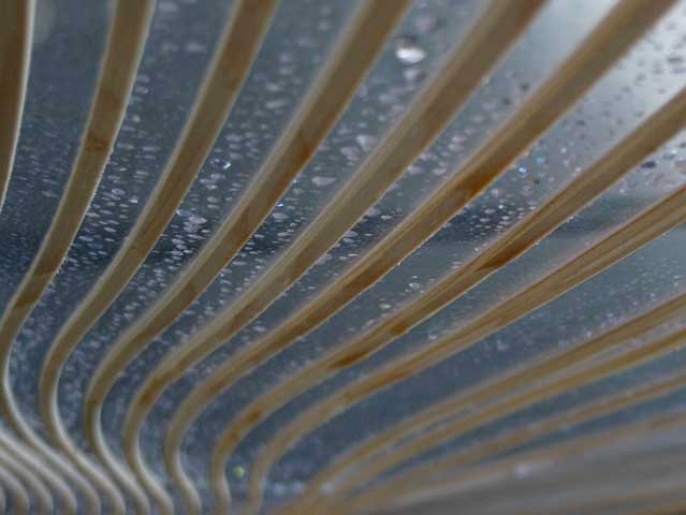

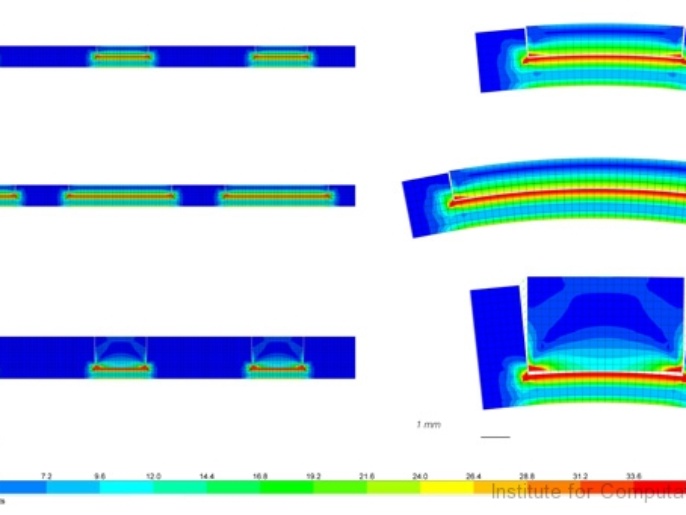

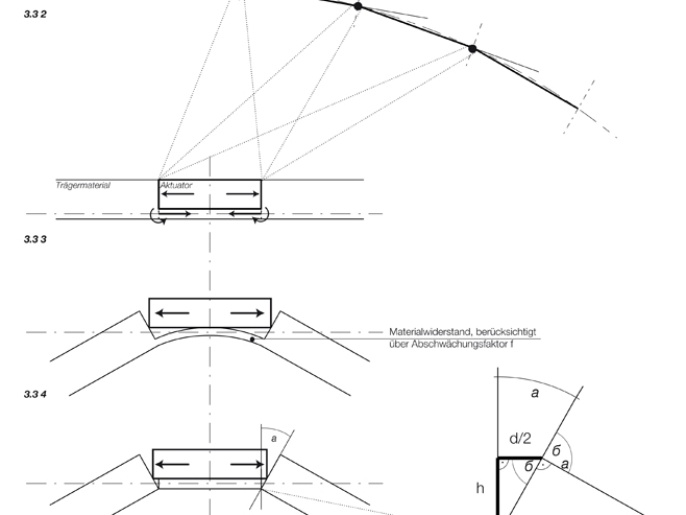

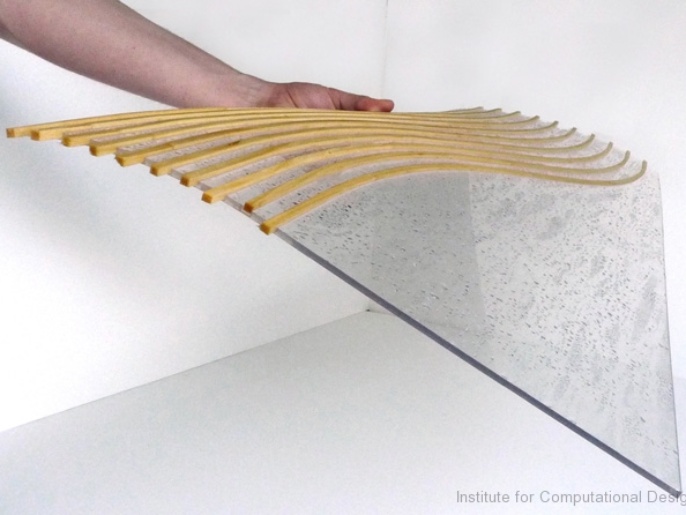

The proposed system consists of just 3 parts. A non-hygroscopic element, a set of grooves, which are milled into this carrier-piece and wood elements, which are inserted into the grooves. Changes in moisture cause the wooden elements – which serve as actuators – to deformation. Even though the system is characterized as a very simple setup of components, a wide range of parameters constitute to its overall form.

For the passive element the material properties are of great concern as well as the overall geometry. The non-hygroscopic behavior is the most important factor in this element. Materials with a low youngs’s modulous are favorable as they are likely to response quicker to the pressure forces exceeded by the actuators. In the case of this project, Perspex was used. This decision was based on multiple factors, amongst them machining and handling possibilities. The groove is only determined by its geometry, most importantly cross section and progression shape.

The wood actuator – the active element within the compound – is characterized by its material properties: the type of wood used, the fibre-direction and the wood-moistuire as well as its overall geometry. For this project, the group decided to maintain the same starting geometry for all actuators. Spruce, originating from cuts resulting in tangential fibre direction, was the chosen material, based on exhaustive experiments in swelling behavior and structural performance.

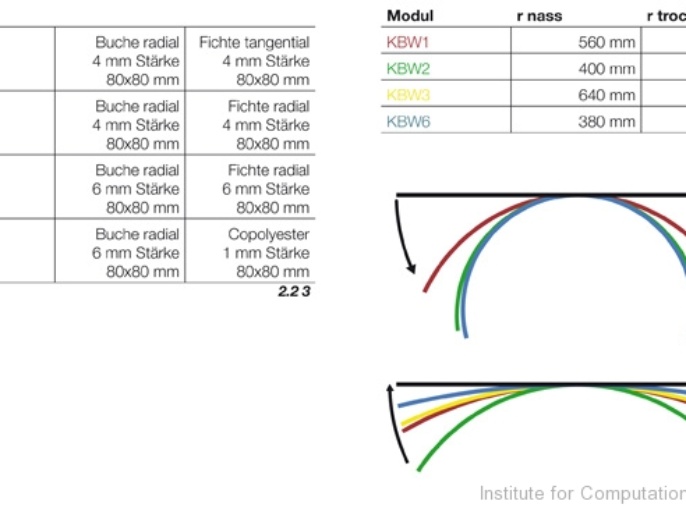

The developed system reacted to moisture by opening and closing without the use of any mechanical joints. The behavior was controlled by specific adjustments to all the above mentioned parameters.

This reactive system is taking advantage of the swelling behaviour of timber. Global changes in form can be achieved through an assembly of local actuators that are inserted into a passive carrier material. The controlling parameters include the actuator's geometry and the depth of insertion as well as a variety of straight and curved patterns.

Material Systems I Studio Brief