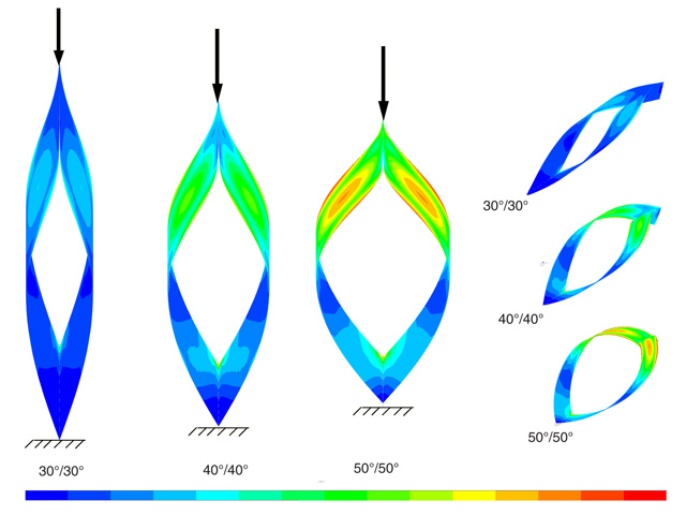

Geometrically identical wooden veneer strips behave differently when exposed to external lateral loads, if the fibres run in different directions. This statement is true for elements of identical humidity and exposure to room temperature. This interesting observation formed the basis for the developed timber material system which was further differentiated by additional parameters such as torsional pre-stressing in longitudinal direction through twisting of individual strips and then fixing them by adding a pin joint at their intersections.

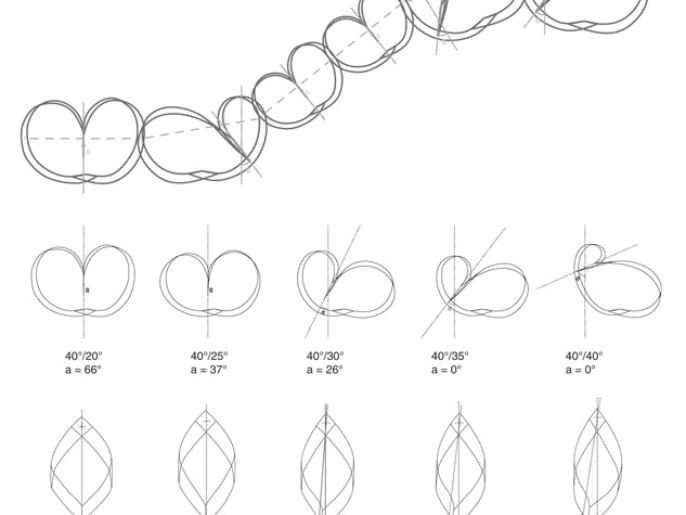

The most important parameter contributing to the systems structural equilibrium state, was the fibre direction, which determined the "Verformungsfigur" of the strips under external loading conditions. A multi-layered strip assembly allowed to articulate the geometries even further / more precisely and added structural capacity to the overall system. The cutting pattern was another important factor, as it allowed for variations in transparency within the system: from "being shut" to a high degree visual porosity. This change in transparency could be articulated gradually.

Depending on the direction of the fibres, multi-dimensional curvature will occur in a straight, axially supported strip when it is bent. The necessary fibre direction and the specific cutout geometry of the desired deformation are calculated through an algorithmic procedure and allow for controlled, complex assemblies.

Material Systems I Studio Brief