Performative Design Methodology based on Robotic Fabrication for Sustainable Architecture

Computational design and fabrication, when synthesized into an integral process, creates a platform for multidisciplinary architectural design including collaborative means for form generation, data analysis, simulation, fabrication and construction. This systematic methodology illustrates a novel approach for material efficient, sustainable design, expanding the tectonic possibilities and design repertoire within the architectural industry.

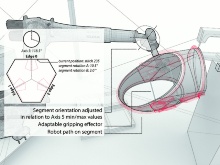

Robotics represents a highly advanced territory in the field of digital design and fabrication. It allows the crossover of multiple design disciplines including architecture, computation, engineering, material science and bionics. Unlike traditional construction methods, robotic fabrication enables a continuous feedback that successfully bridges the gap between design (intent), computation (abstraction), simulation (behavior), optimization (performance) and the resulting building (realization). This research project is intended to explore design and fabrication methodologies for the implementation of robotic processes in sustainable architectural design. As part of this research project, the Digital Design and Research Center (DDRC) from Tongji University and the Institute for Computational Design (ICD) from the University of Stuttgart will collaborate to develop integrative computational methods and robotic fabrication processes, as well as example material systems that will be tested in a series of large scale architectural demonstrators.

PROJECT TEAM

ICD Institute for Computational Design and Construction, University of Stuttgart

Prof. A. Menges (PI)

Martin Alvarez, Oliver David Krieg, Dylan Wood

DDRC Digital Design and Research Center, Tongji University, Shanghai

Prof. Yuan Feng

PROJECT FUNDING

Sino-German Center for Research Promotion (DFG and NSFC)