Design, fabrication and engineering methods for the application of curved wood components for high-performance and resource-efficient wood construction: Project Tower Urbach, Remstal Gartenschau 2019

Project Report (DE):

https://www.dbu.de/projekt_34714/01_db_2848.html

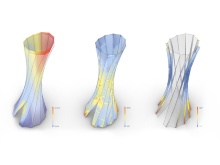

The aim of the project is to use innovative, high curvature timber components for load-bearing, resource-efficient building structures. Suitable planning, production and design methods are being developed for this purpose. These methods will be applied in the realization of a building demonstrator for the project: Urbach Turm at the Remstal Garden Show 2019.

Wood is one of the most sustainable building materials. The regional availability, favorable energy and CO2 balance, high social acceptance as well as the potential to strengthen the regional value chains offer an excellent basis for the development of innovative, resource-saving construction methods. The market for prefabricated timber components, in particular BSPH (CLT – Cross Laminated Timber) systems, is currently growing rapidly. These systems offer high-precision manufacturing with short construction times on site and significantly reduce the negative impact of construction sites and waste on the environment. In timber construction, however, components are typically flat plates, straight beams, or slightly curved beams. Curved components represent only a small portion of the market with a process that is associated with high costs and that involves demanding wood processing, large amounts of material waste and high machining costs. Curvature can significantly increase the load-bearing capacity of a building component and at the same time significantly reduce material requirements. However, the aforementioned factors have so far excluded wood from use for high load-bearing curved building structures in favor of less environmentally friendly materials such as concrete, steel or plastics. The innovative character of this project consists of the development and application of new, high curvature BSPH (CLT) building systems. The advantages of the systems will expand the use of timber as a fully sustainable building material.

Publications:

Wood, D., Grönquist, P., Bechert, S., Aldinger, L., Riggenbach, D., Lehmann, K., Rüggeberg, M., Burgert, I., Knippers, J., Menges, A.: 2020, From Machine Control to Material Programming: Self-Shaping Wood Manufacturing of a High Performance Curved CLT Structure -- Urbach Tower, in Burry, J., Sabin, J., Sheil, B., Skavara, M. (eds.), Fabricate 2020: Making Resilient Architecture, UCL Press, London, pp. 50-57. (ISBN: 978-1-78735-812-6 ) link

Bechert, S., Aldinger, L., Wood, D., Knippers, J., Menges, A.: 2021, Urbach Tower: Integrative structural design of a lightweight structure made of self-shaped curved cross-laminated timber. Structures, 33, 3667--3681. (DOI: 10.1016/j.istruc.2021.06.073) link

Aldinger, L., Bechert, S., Wood, D., Knippers, J., Menges, A.: 2020, Design and Structural Modelling of Surface-Active Timber Structures Made from Curved CLT – Urbach Tower, Remstal Gartenschau 2019, in Gengnagel, C., Baverel, O., Burry, J., Ramsgaard Thomsen, M., Weinzierl, S. (Eds.), Impact: Design With All Senses [Proceedings of the Design Modelling Symposium 2019], Springer International Publishing, Cham, pp. 419-432. (doi: 10.1007/978-3-030-29829-6 33)

PROJECT TEAM

ICD Institute for Computational Design and Construction, University of Stuttgart

Dylan Wood, Prof. A. Menges

ITKE Institute of Building Structures and Structural Design

Lotte Aldinger, Simon Bechert, Prof. J. Knippers

ASSOCIATED RESEARCH PARTNERS

Laboratory for Applied Wood Materials, Swiss Federal Institute of Material Science and Technology (Empa) / Wood Materials Science, Institute of Building Materials, ETH Zürich

Dr. Markus Rüggeberg, Philippe Groenquist, Prof. I. Burgert

ASSOCIATED INDUSTRY PARTNERS

Lehmann Holzwerk AG, Erlenhof, Switzerland

Blumer- Lehmann AG, Erlenhof, Switzerland

IMPLEMENTATION PARTNERS

Remstal Gartenschau 2019

PROJECT FUNDING

Deutsche Bundesstiftung Umwelt (DBU)

PROJECT INFORMATION

Dylan Wood, University of Stuttgart, Institute for Computational Design and Construction