ICD Sewn Timber Shell 2017

Inaugural Exhibition of the Design Society, Shenzhen, 2017

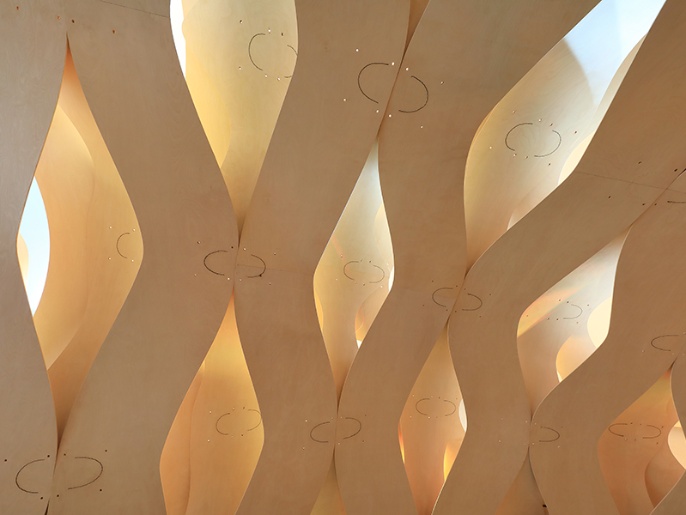

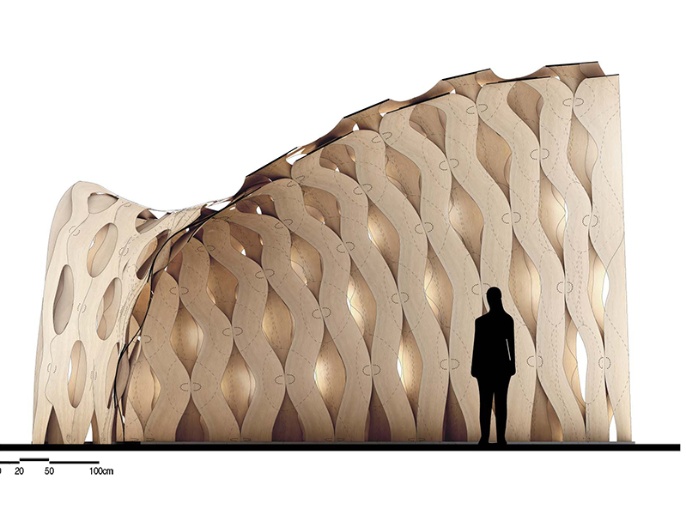

The Sewn Timber Shell investigates the use of robotics and sensing mechanisms in combination with garment design and industrial sewing techniques to explore a new way of fabricating tailored wood structures and re-engaging with traditional craftsmanship.

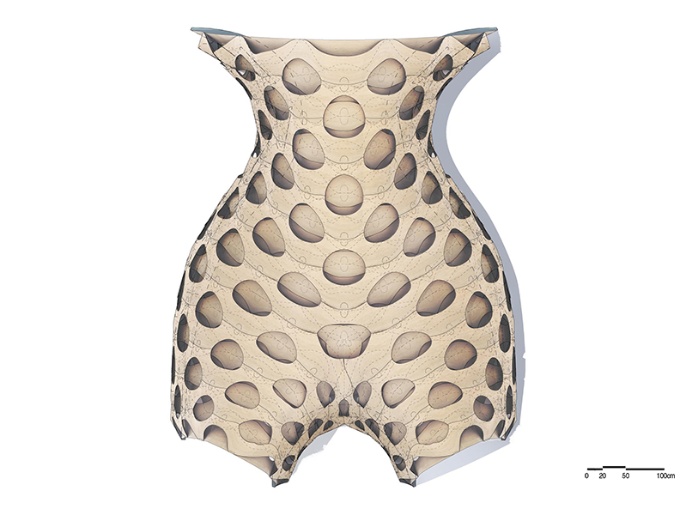

The related research studies traditional garment patterning and connection techniques still used in fashion today and re-interprets them in a new material context. Fabric is replaced by thin sheets of plywood, which establishes an altered relation between material pliability and stiffness and thus introduces loadbearing capacity to the novel material system. Sewing plays a similar role as in garment design, as the seams enable tailoring three-dimensional curved shapes from a flat sheet material that envelope the body. If applied on an architectural scale, the seams become connections that shape the material based on the elastic bending of wood, which creates structural capacity and spatial enclosure.

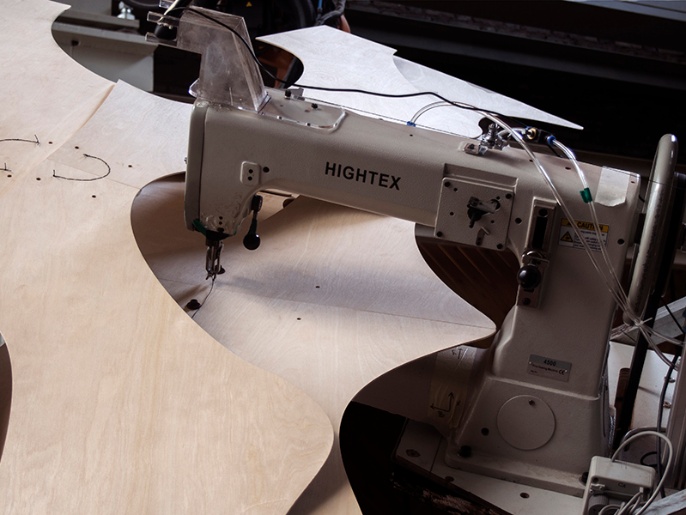

An adaptive robotic fabrication process enables the necessary scaling-up and the handling of the complex interrelations between the patterning shapes and the material behavior. In contrast to repetitive manufacturing processes, where automation relies on the execution of predetermined and fully defined steps, here sensing technology is employed to enable a workflow that synthesizes material computation and robotic fabrication in real time. In this process, the shape of the tailored work piece is repetitively scanned. The segments contain previously made connections in the form of markers that are tracked live for the generation of the robotic movement. Throughout that process, the wood pieces are sequentially added and permanently joined by a sewn connection. A custom digital modelling design tool is used to derive a porous, undulating, triple-layered system that coherently integrates material properties, fabrication constraints and assembly sequence. This intricate play between materiality and materialization results in a sewn shell that extends the characteristics of wood architecture and at the same time unfolds a unique textural and spatial articulation.

The Sewn Timber Shell 2017 is a collaborative project by the Institute for Computational Design and Construction (ICD) at Stuttgart University and the Digital Design Research Center (DDRC) at Tongji University, Shanghai that forms part of the Sino-German Research Project “Performative Design Methodologies based on Robotic Fabrication for Sustainable Architecture (GZ 1162)” funded by the Sino-German Research Centre.

The project will be on show at the inaugural exhibition "Minding the Digital" of the Design Society, China's new leading design museum in Shenzhen.

Project Team

ICD Institute for Computational Design, University of Stuttgart

Martín Alvarez, Prof. Achim Menges

DDRC Digital Design Research Center, Tongji University

Prof. Philip Yuan

Research collaborators

Chai Hua, Samuel Leder, Valentina Soana, Iván Jimenez

SINO-GERMAN RESEARCH PROJECT GZ 1162

Performative Design Methodology based on Robotic Fabrication

Digital Design Research Center Tongji University Shanghai (Prof. Philip Yuan)

Institute for Computational Design and Construction (Prof. Achim Menges)